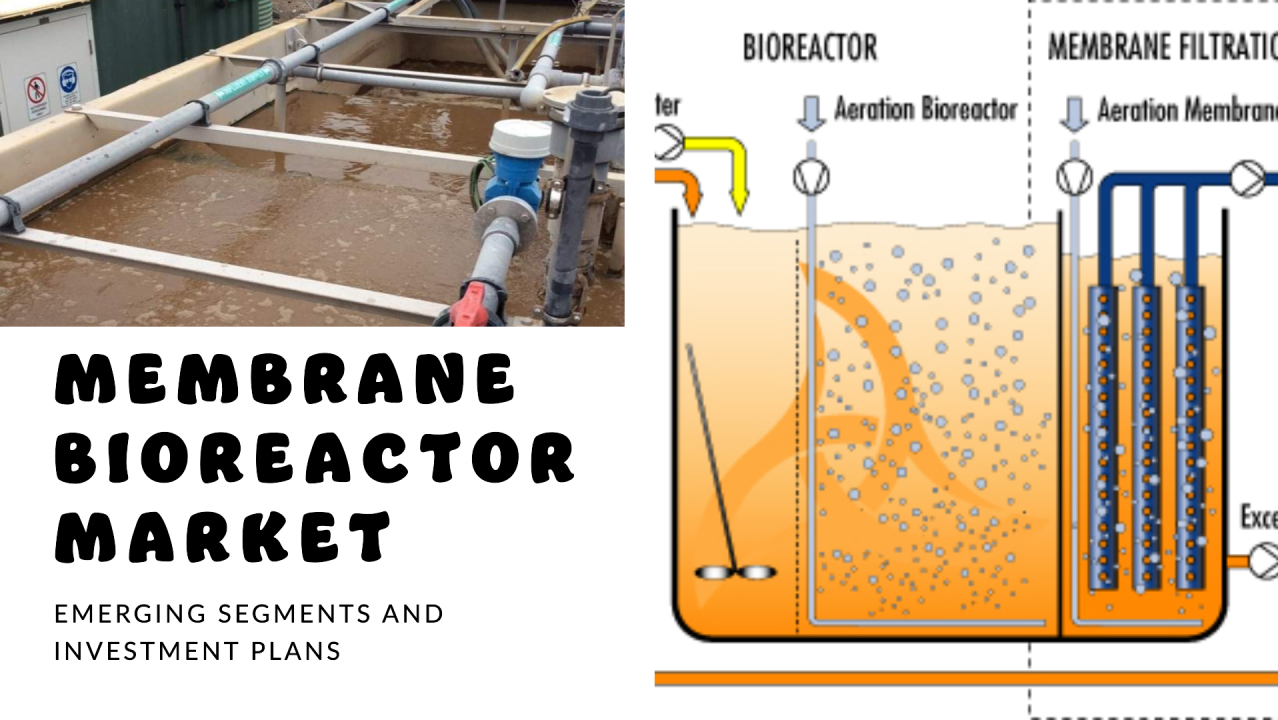

A Membrane Bioreactor (MBR) is a technology used in wastewater treatment that combines biological treatment processes with membrane filtration. In traditional wastewater treatment plants, biological processes are employed to break down organic pollutants using microorganisms, and then the treated water is separated from the sludge through sedimentation or settling processes.

In an MBR system, instead of relying solely on sedimentation for solid-liquid separation, membranes are used to physically separate the treated water from the biomass (microorganisms) and suspended solids present in the wastewater. These membranes act as barriers, allowing water molecules to pass through while retaining particles, microorganisms, and macromolecules.

Download PDF Brochure @ https://globalmarketvision.com/sample_request/315224

The global membrane bioreactor market is projected to reach USD 4.9 billion by 2026, growing at a cagr 8.3% from 2021 to 2026. The increase in demand for MBRs in emerging economies of Asia Pacific and South America is due to the rising water scarcity, growing demand for clean water, and high-quality effluents some of the factors driving the market for MBR.

MBR Market Dynamics

Driver: Growing demand for advanced wastewater treatment technology for more efficient and high-quality treated water

MBR is an emerging technology which is capable of handling various water impurities such as suspended solids, pathogens, bacteria, nitrogen, and other contaminants that are mostly present in municipal and industrial waste. MBR is more effective than existing activated sludge process (ASP) and moving bed biofilm reactor technologies for wastewater treatment. MBR Membranes such as hollow fiber, flat sheet, and multi-tubular are made of various polymeric materials such as PVDF, PE, PES, and others which are generally used for microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO). MBR offer higher sludge concentrations and lower reactor volumes than conventional systems, resulting in lower sludge production. Moreover, MBR has long solid retention times (SRT) resulting in improved biological treatment. An MBR system is a proven technology to avoid the spread of the emerging micro pollutants in the environment by treatment of wastewater for reuse.

Opportunity: Increasing demand for high-quality effluents

Rising demand for high quality effluent owing to the stringent regulations implemented by various countries on discharge standards is increasing the demand for MBR system. MBR offer superior quality and consistency of the produced effluents by eliminating biological wastes and bacteria, such as E. coli, which are measured to be less than 3 mm. Standards. MBR overcomes the problems associated with poor sludge setting in the activated sludge process, and MBR adoption is increasing globally owing to its efficient performance in compliance with regulations. This creates an opportunity for MBR in various end-use applications in oil & gas, food & beverage, pharmaceutical, municipal, and other sectors.

In terms of value, municipal wastewater treatment to be the fastest-growing application segment of the MBR market, during the forecast period.

Municipal wastewater treatment accounts for the largest share during the forecast period as the total flow of sewage is greater than that of industrial effluents. The MBR system are capable of handling the large municipal flows and can be installed as a retrofit in existing plants for increasing the plant capacity. Municipal wastewater is treated to meet statutory requirements for discharge to the environment. MBR technology eliminates suspended solids, organic matter, ammonia, nitrates, phosphate, pathogenic bacteria, and micropollutants. Moreover, the compact size of MBR allows the system to be installed in existing plants providing cost benefits to the end-users.

APAC is expected to be the fastest-growing market during the forecast period.

Based on region, the MBR market has been segmented into APAC, Europe, North America, South America, and Middle East & Africa. Asia Pacific countries such as China and India is expected to witness high growth, owing to industrialization and growing awareness on water reuse and recycling. Moreover, the introduction of various initiatives, laws, and regulations by government bodies such as environmental protection laws to conserve natural water resources sanitation management are expected to positively impact the MBR market.

Key Market Players

Major players operating in the global MBR market are SUEZ (France), Kubota Corporation (Japan), Evoqua Water Technologies (US), Mitsubishi Chemical America (Japan), Toray Industries, Inc. (Japan), CITIC Envirotech Ltd Ltd (Singapore), Koch Industries Separation Solutions (US), Alfa Laval (Sweden), Veolia (France), and Aquatech International LLC (US).

This research report categorizes the MBR market is segmented by membrane type, by system configuration, by applications and region

On the basis of membrane type, the MBR market has been segmented as follows:

- Hollow fiber

- Flat sheet

- Multi-tubular

On the basis of system configuration, the MBR market has been segmented as follows:

- Submerged

- External

On the basis of applications, the MBR market has been segmented as follows:

- Municipal wastewater treatment

- Industrial wastewater treatment

On the basis of region, the MBR market has been segmented as follows:

- Asia Pacific

- Europe

- North America

- South America

- The Middle East & Africa